Installation instructions for Electraeon Fast Throttle Cam

StreetFighter, 848, 1098, 1198 only.

Be sure that you have the correct Electraeon Fast Throttle Cam for your motorcycle. Attempting to install the incorrect model will cause installation difficulties and poor performance.

Tools Required: Small size Metric combination wrenches, socket set, screw drivers, Torx 20 driver, 2.5mm L Allen Wrench, Electronic Multi Meter, Permatex Penetrating grade thread locking compound #765-1148, 242 Loctite (Blue) service removable grade thread locking compound or equivalents, Safety Glasses. For the spring mod: Dremel Moto Tool with small cut off blades, shop vice, two sets of needle nose pliers.

Remove Throttle Grip and Air Box with throttle bodies attached according to the Service Manual.

Place the Air Box, Throttle Body on a workbench.

Remove Throttle Cables from the stock Throttle Cam.

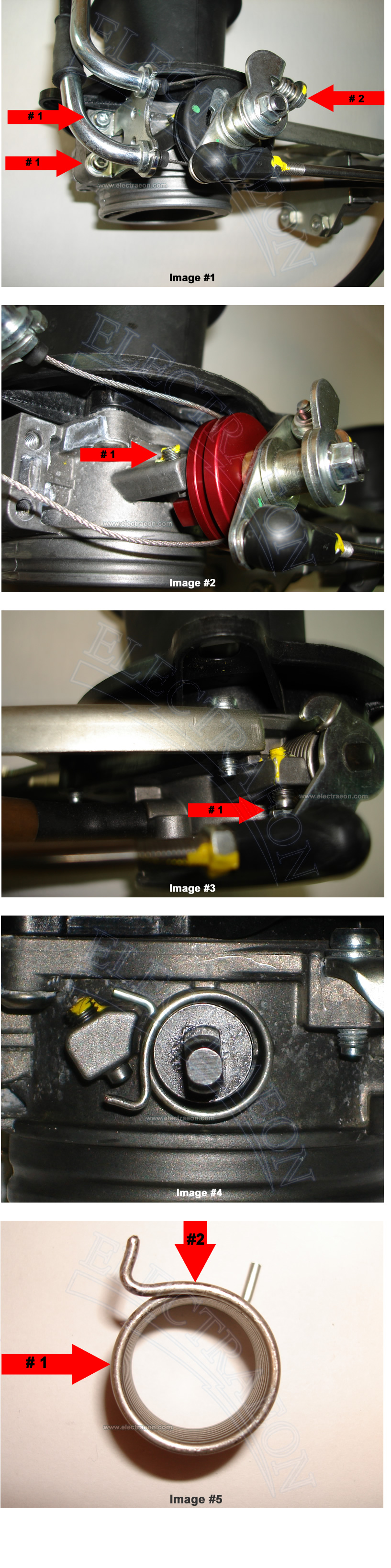

Remove the Throttle Cable Mount Bracket with Throttle Cables attached with a Torx T-20 driver tool (image #1, Item #1).

Using an Electronics Digital Multi Meter set to measure Ohms of resistance in the 1000 Ohm range, measure the resistance across the forward 2 pins of the 3 throttle position sensor connector. Use the forward 2 pins as the throttle body would be mounted on the bike. Open and slowly close the butterflies by rotating the stock Throttle Cam. Notice that the resistance increases as the butterflies are opened. Record the results in the closed position on a sheet of paper. Measure and record several times. Be sure that you are getting a consistent result. Measurements of approximately 1170 ohms are typical.

Remove the nut securing the stock Throttle Cam with a 10mm wrench.

Slide the Adjuster Assembly off of the Butterfly shaft. Pay close attention to the orientation of all parts.

Slide stock Throttle Cam off of the Butterfly Shaft. Pay close attention to the orientation of the Cam and Spring.

It is possible to use only 1 throttle Spring. Use of 1 Spring will reduce the amount of force required to turn the hand grip. If you would prefer to use both springs, modify the stock spring as described in the next section. It is not possible to use an unmodified Spring with the Fast Throttle Cam.

Install modified Spring (if used) along with Fast Throttle Cam in the same orientation as the stock Cam (Image #4).

Adjust the Throttle Cam Stop Screw (image #2, Item 2) to obtain the same Ohm reading with the Butterflies in the closed position using the technique described above. Following adjustment the ohms measurement must exactly match the measurements taken with the stock Throttle Cam. Use a 2.5mm L shaped Allen Key to make the adjustment. Apply penetrating grade loctite to the set screw after adjustment.

Install the Throttle Cable Mount Bracket with Throttle Cables attached with a Torx T-20 driver tool. Use Blue Loctite on the threads of the screws, be careful to avoid cross threading the fasteners.

Install Brass Spacer, then Adjuster Assembly. Install Nut loosely. Be VERY careful to avoid cross threading the Nut. Be sure that the flange on Spacer of the Adjuster Assembly seats though the hole on the Adjuster Arm (see image #2) .

Adjust the Set Screw on the Adjuster Assembly (image #1, Item 2) so that the Rear Throttle Body Cam rests on it's set screw when the Butterflies are in the closed position (image #3, item 1). Adjust the Set Screw on the Adjuster Assembly ONLY do not make any adjustments on the Rear Throttle Body. Apply penetrating grade loctite to the set screw after adjustment.

Torque the Cam Nut. Do not over tighten.

Install Air Box, Throttle Body, Throttle Grip, and Adjust Throttle Cables per Service Manual instructions.

Spring modification:

Always wear safety glasses when working with springs and grinders.

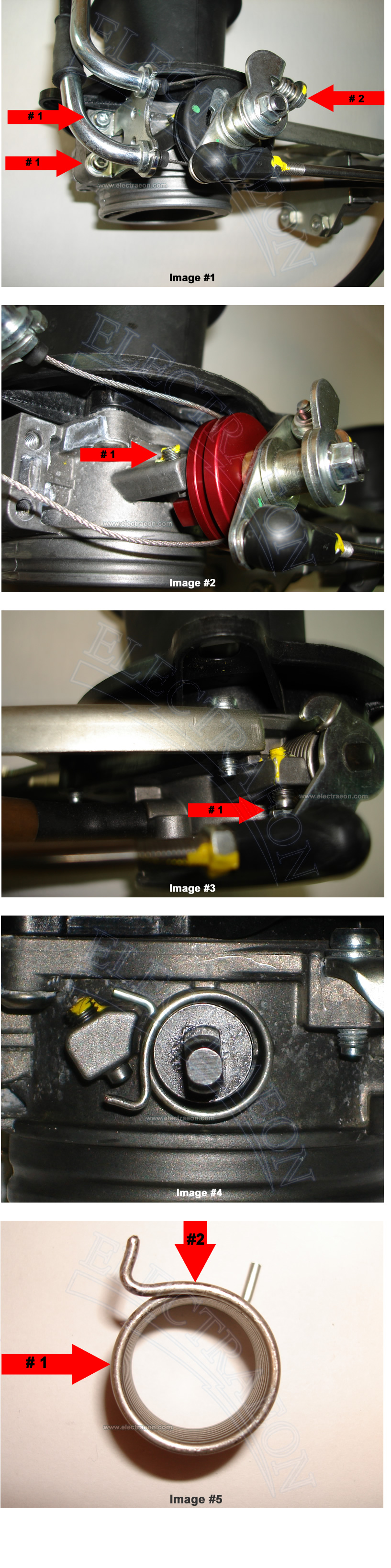

Place spring in vice with the hooked end of the spring up. Count 9 coils at point #2 in image 5. Place a screw driver between the 8th and 9th coils to space the coils apart for cutting. Use a Dremel with a cut off blade to cut the hooked end at point 1 in image 5. Bend the wire to the shape shown. Do not use heat to assist in bending the spring. Install as shown above with the newly belt portion of the spring pressing on the back of the throttle stop on the Fast Throttle Cam. Rotate the cam to test spring before continuing with the installation. You will notice a reduced amount of force is required to turn the Cam compared to stock.

Testing: Rotate the throttle grip several times. Throttle grip operation should feel smooth and the throttle spring should return the throttle to the closed position when released. Start the motorcycle in riding position with the transmission in neutral. Turn the handle bars from lock to lock. The engine idle speed should not change with handle bar position. If idle speed changes by moving the handle bars the throttle cables are too tight.